Technology

Technology

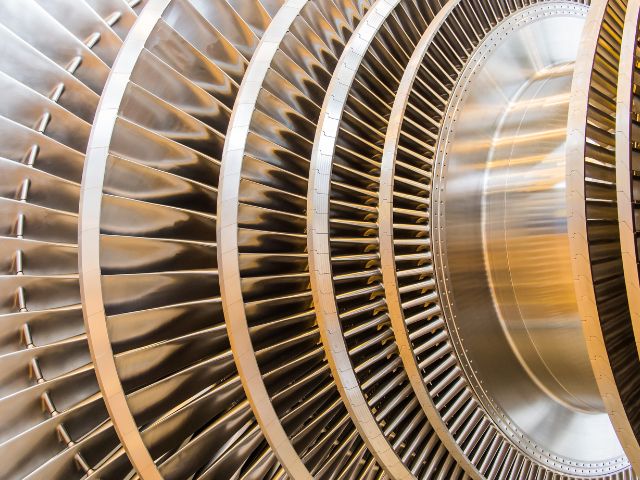

Misalignment in steam turbines can sometimes happen, unfortunately. Understanding what causes misalignment in steam turbines can help you catch these issues early and avoid costly maintenance repairs. These large machines should operate at peak performance to handle their job correctly. Continue reading to learn more about misalignment.

Misalignment can cause serious problems with your steam turbine, especially since it’s the number one cause of rotating and turbine equipment failure. Shaft misalignment can cause rotor bending, cascading impacts, and excessive vibration, leading to reduced seal life and premature bearing failure.

This condition is one that compounds itself. If you don’t take care of the problem, it’ll become bigger and more costly. You can deal with total equipment failure and replacement.

Misalignment means the centerline of the motor shaft isn’t in line with the centerline of the drive shaft. A technician will measure the distance between the two. Preventative maintenance helps catch misalignments early and can reduce the cost of turbine repairs. These machines don’t tolerate much alignment variance, and that’s why alignment is so important. Now let’s get into the causes of misalignment.

If the foundational bearing pads and turbine casings have a poor connection, this can end in misalignment in the steam turbine. The torque in the casing will tip when the pad experiences stop sliding or increased friction during thermal expansion in the axial direction. This force causes misalignment between the bearing surface and casing. You’ll notice a vibration in the bearing pad stall, foundation frame support, and forward end of the turbine.

Expansion and contraction from temperature fluctuations cause casing problems that lead to misalignment. If the turbine starts from a hot condition, the stationary diaphragms and rotating blades could rub and cause damage and misalignment. Also, insufficient thermal isolation can lead the turbine cylinders to have temperature fluctuation. You’ll need to use steam turbine troubleshooting measures to figure out which of the above casing problems is behind the misalignment.

Stay on top of your steam turbine’s preventative maintenance to reduce misalignments and other costly issues. Understanding what causes misalignments in steam turbines can help you catch them early. You want these machines to operate efficiently and effectively.

24World Media does not take any responsibility of the information you see on this page. The content this page contains is from independent third-party content provider. If you have any concerns regarding the content, please free to write us here: contact@24worldmedia.com