Business

Business

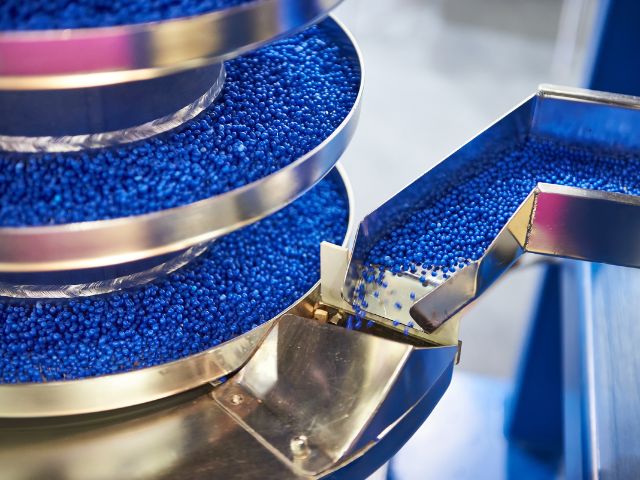

In the modern manufacturing sector, plastics are vital to many of our day-to-day products. For those in the manufacturing sector, understanding the intricate connection between plastic and the end products is essential for success. This post explores several key products that use plastic in their manufacturing process and how this versatile material shapes our global world.

With their sleek designs and precision engineering, consumer electronics often hide a crucial material beneath their surfaces. The casings of smartphones, laptops, and TVs, the insulation of your electrical wiring, and the components of high-tech medical devices heavily depend on various forms of plastic. Plastics’ lightweight and durable nature makes them ideal for parts that need to protect against electrical hazards, reduce weight in portable devices, and offer design flexibility to accommodate developing technologies. For manufacturers in the electronics industry, plastic is a calculated necessity in ensuring products can withstand the rigors of everyday life.

The automotive industry is another sector where plastic has made significant inroads. While steel and aluminum remain the staple materials for structural components, plastics are vital in modern cars for many use cases. From bumpers and interior trim to gaskets and engine components, the high strength-to-weight ratio and resistance to corrosion and chemicals make plastic a mainstay in automotive manufacturing. Furthermore, innovations in composite plastics can enhance the safety features of cars when used in bumpers and other areas where impact resistance is paramount.

High-performance plastics offer an excellent balance of properties that meet the stringent regulatory requirements of healthcare alongside the manufacturing capabilities to produce intricate and tailored components. MRI and X-ray machines, blood bags, and components used in life-saving devices, such as ventilators and defibrillators, all contain critical plastic parts. For manufacturers in the medical sector, the use of plastics poses unique challenges related to biocompatibility, sterilization, and traceability of materials.

When thinking of plastic-heavy sectors, the construction industry may not immediately come to mind, but the material has radically transformed how we build and maintain structures. PVC pipes, insulation, window frames, and various cladding products are made from plastics, offering superior durability, thermal insulation, and resistance to the elements. The development of new plastics that can withstand the test of time while also being recyclable is a testament to the sector’s commitment to a greener future. By understanding how to choose the right plastic for fabrication, manufacturers can meet the market’s growing demands and contribute to sustainability efforts.

The key products that use plastic in their manufacturing process have transformed our world in various ways. It’s a game-changer in regard to cost, design, and environmental impact. By continually exploring new materials and processes, businesses can leverage this versatile material for the continued advancement of our global manufacturing output.

24World Media does not take any responsibility of the information you see on this page. The content this page contains is from independent third-party content provider. If you have any concerns regarding the content, please free to write us here: contact@24worldmedia.com